-

Views:3253

Built for failure analysis and material engineering research, the OLS5100 laser microscope combines exceptional measurement accuracy and optical performance with smart tools that make the microscope easy to use. Precisely measure shape and surface roughness at the submicron level quickly and efficiently to simplify your workflow with data you can trust.

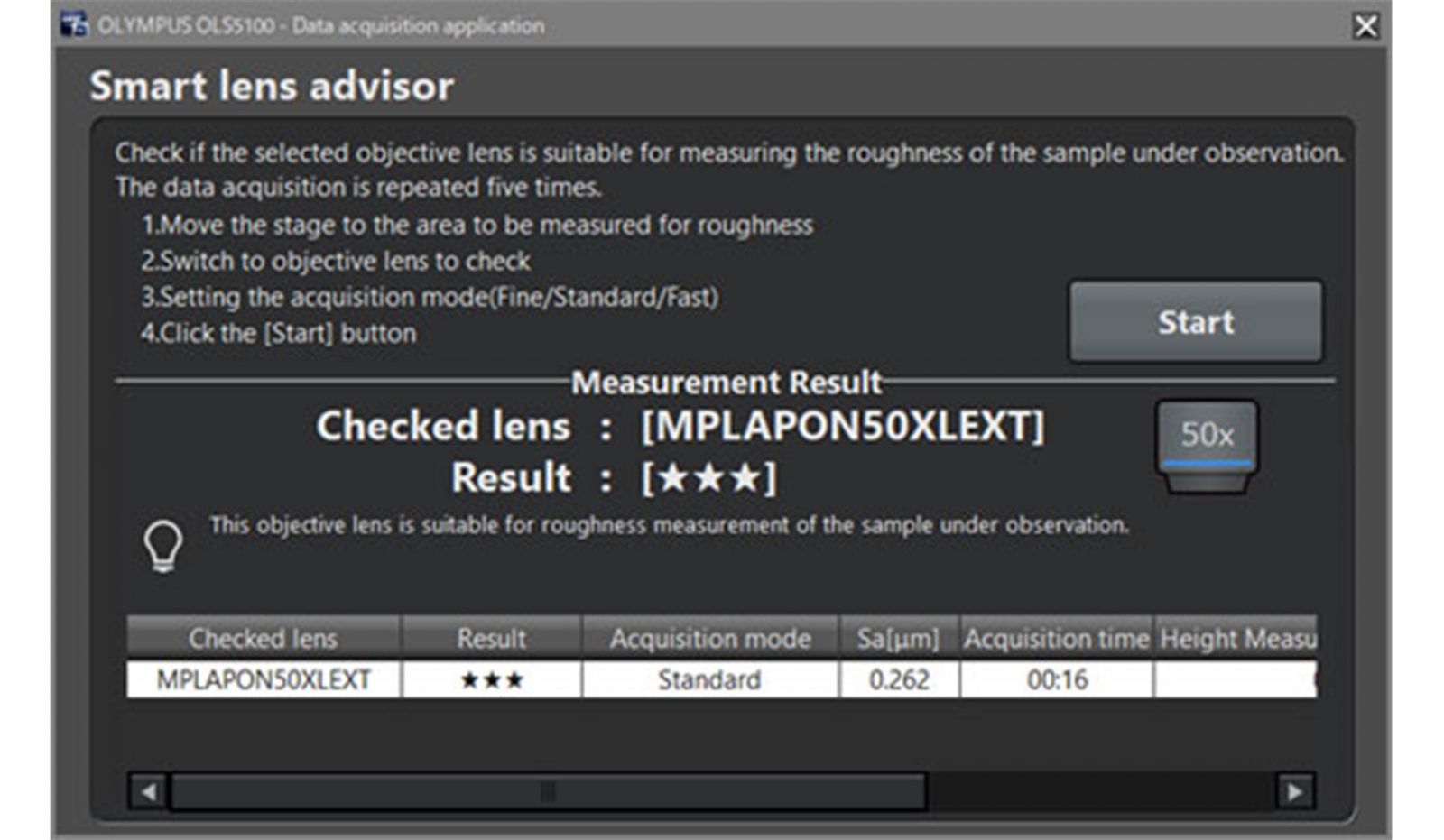

LEXT microscope objectives deliver highly accurate measurement data. Paired with the Smart Lens Advisor, you can acquire accurate data you can be confident in.

* Guaranteed measurement accuracy*

* Renowned Olympus optics reduce aberration to capture the correct shape of your sample throughout the entire field of view

* Smart Lens Advisor helps you choose the right objective lens for your roughness measurement

Simple Material Engineering and Failure Analysis Experiment Management

Managing experiment conditions when testing new materials is complicated, so the OLS5100 laser microscope’s Smart Experiment Manager simplifies the process by automating key steps, such as creating the experiment plan.

*Compared with OLS5000

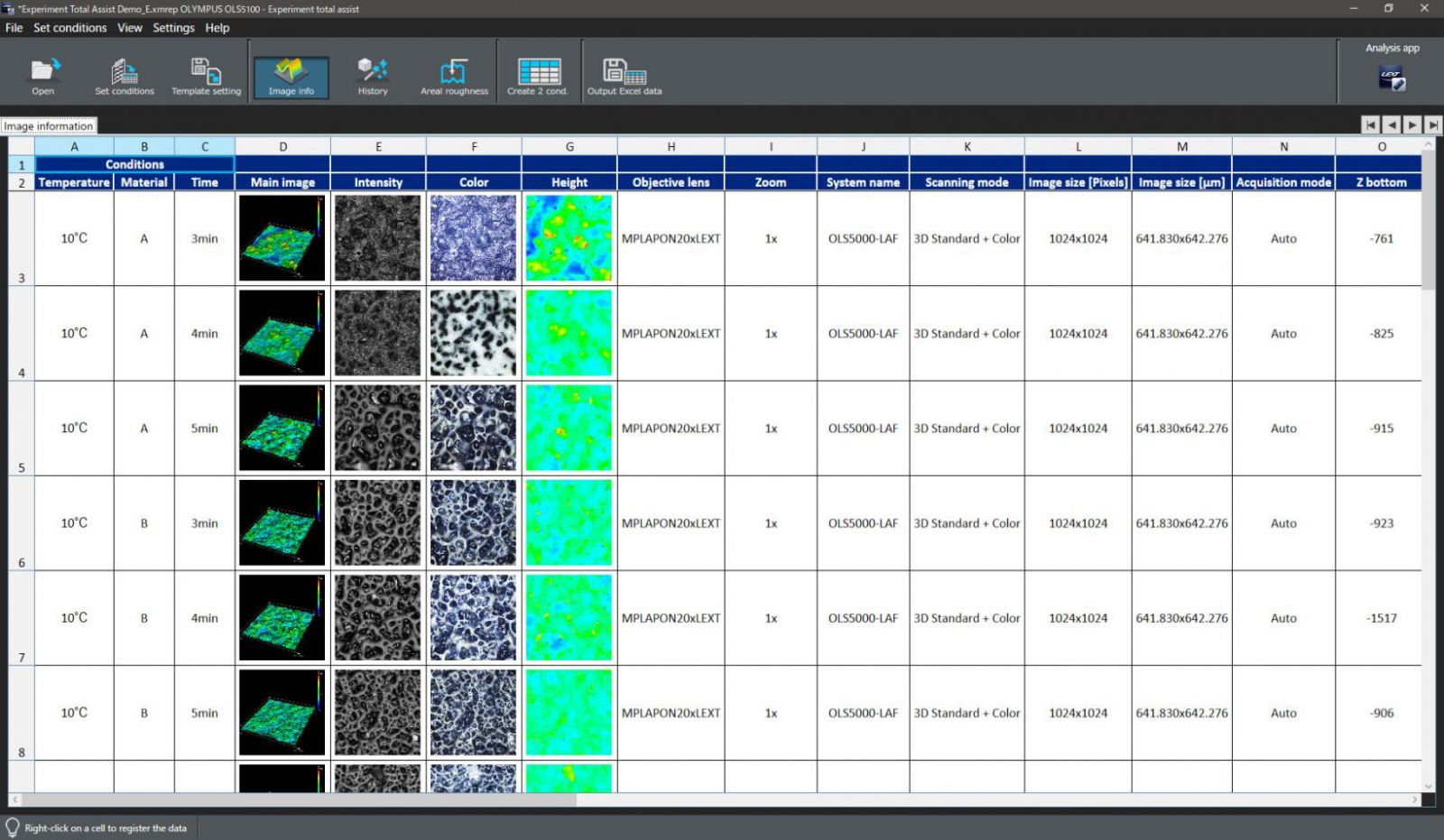

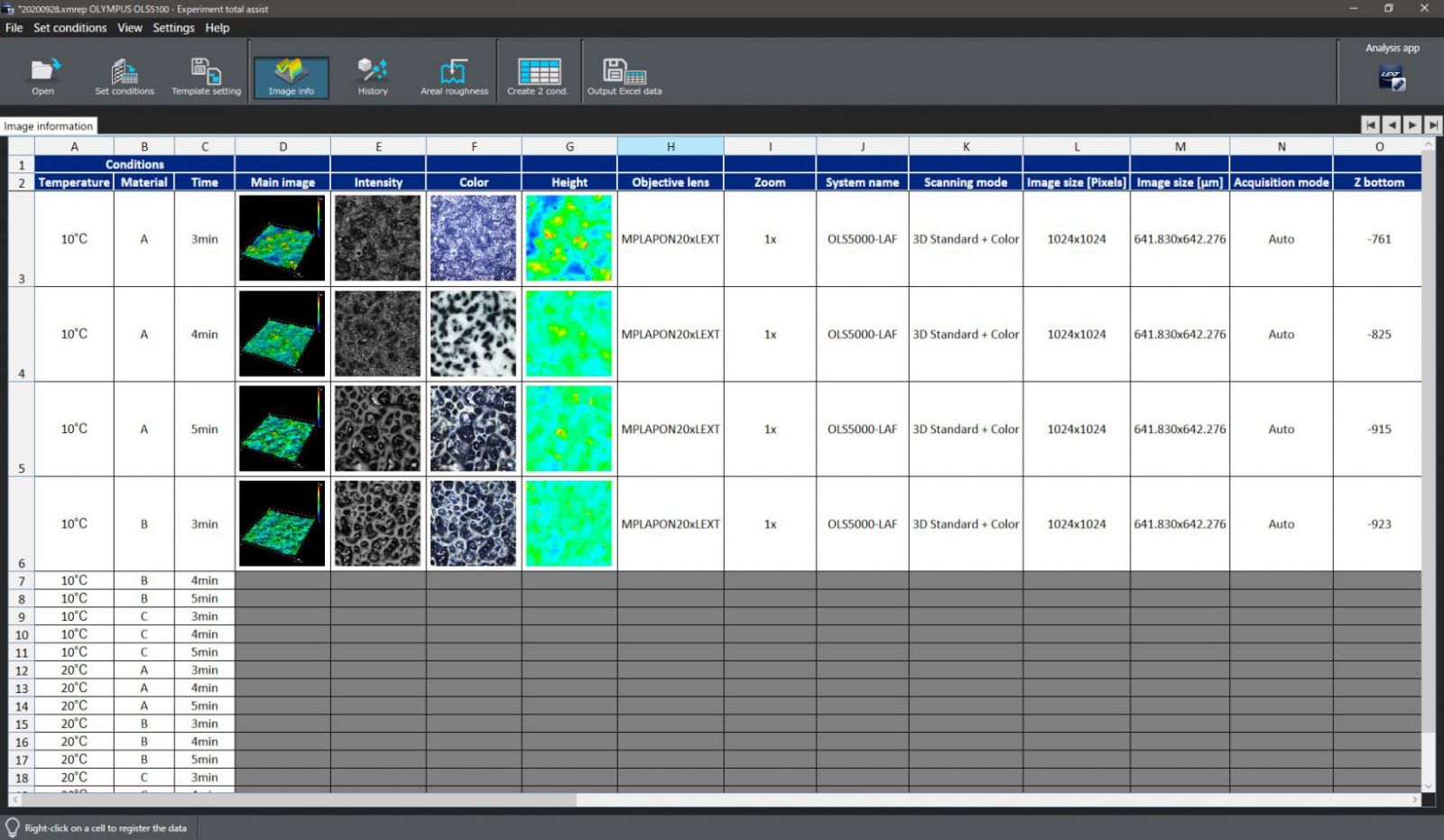

Automatic Data Input

The software automatically adds values to your experiment plan matrix to minimize the chance of input errors. In just a couple of clicks, you can export your data to an Excel spreadsheet.

Easy Experiment Condition Data Organization

You can click on each cell in the experiment plan, and the software will automatically generate a file name that contains the evaluation conditions for easy record keeping. Each file contains the associated images and data.

.jpg)

Comprehensive Data Capture

The microscope scans your sample according to the experiment plan generated by the software so you know you’re not missing data or redoing work.

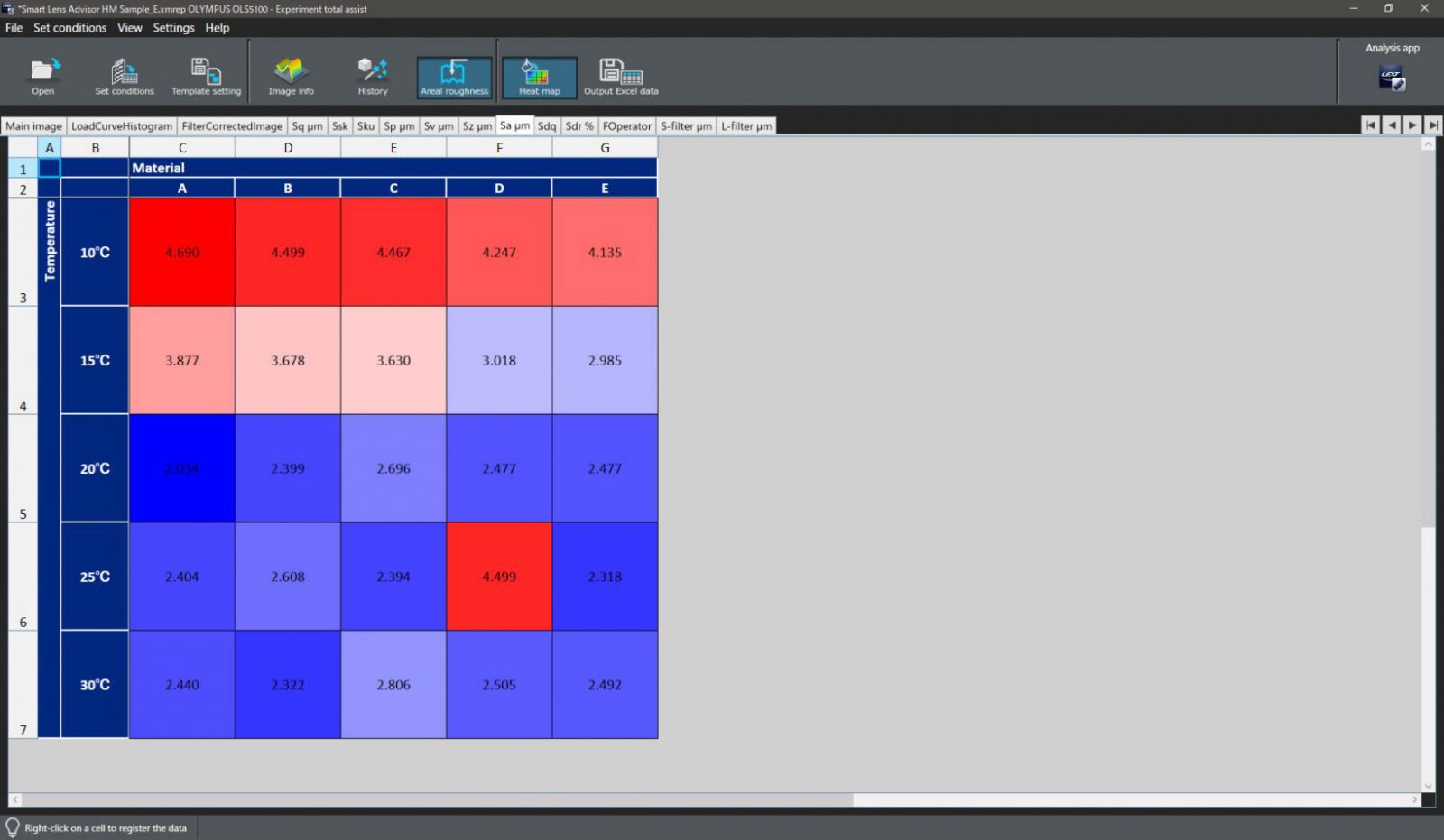

Find Data Problems Easily

A color map helps you understand your experiment data and verify that no data are missing and there are no errors. If there’s a problem, you can find and fix it earlier in the process.

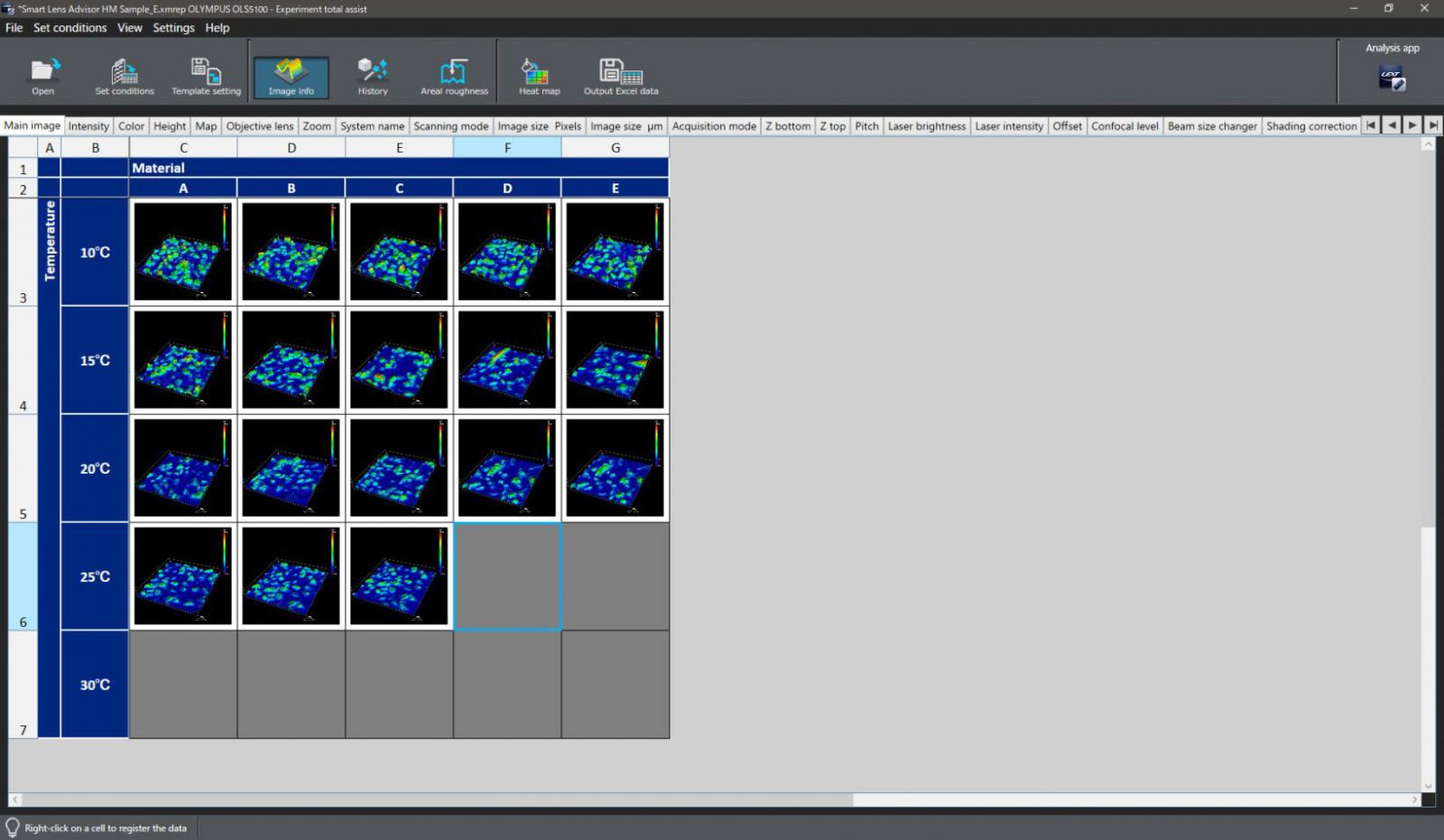

Choose the Right Objective Lens

The Smart Lens Advisor helps you choose the right objective lens for your surface roughness measurement application. Enter some basic information—such as the field of view and the lens you want to use—and the Advisor will tell you how suitable it is for the application.

Easy Data Acquisition

Experienced and novice users alike can acquire data quickly and easily with the Smart Scan II feature. Place the sample on the stage, press the start button, and the microscope does the rest.

| Model | OLS5100-SAF | OLS5100-SMF | OLS5100-LAF | OLS5100-EAF | ||

|---|---|---|---|---|---|---|

| Total magnification |

54x–17,280x |

|||||

| Field of view |

16 µm–5,120 µm |

|||||

| Measurement principle | Optical system | Reflection-type confocal laser scanning laser microscope Reflection-type confocal laser scanning laser-DIC microscope Color Color-DIC |

||||

| Light receiving element | Laser: Photomultiplier (2 channels) Color: CMOS color camera |

|||||

| Height measurement | Display resolution | 0.5 nm | ||||

| Dynamic range | 16 bits | |||||

| Repeatability σn-1*1 *2 *5 | 5X:0.45 μm, 10X:0.1 μm, 20X : 0.03 μm, 50X : 0.012 μm, 100X : 0.012 μm | |||||

| Accuracy *1 *3 *5 | 0.15+L/100 μm (L:Measuring length[μm]) | |||||

| Accuracy for stitched image *1 *3 *5 | 10X:5.0+L/100 μm, 20X or higher : 1.0+L/100 μm (L: Stitching length [μm]) | |||||

| Measurement noise (Sq noise) *1 *4 *5 | 1 nm (Type) | |||||

| Width measurement | Display resolution | 1 nm | ||||

| Repeatability 3σn-1 *1 *2 *5 |

5X: 0.45 µm, 10X: 0.1 µm, 20X: 0.03 µm, 50X: 0.012 µm, 100X: 0.012 µm |

|||||

| Accuracy *1 *3 *5 | Measurement value +/- 1.5% | |||||

| Accuracy for stitched image *1 *3 *5 | 10X : 24+0.5L μm, 20X : 15+0.5L μm, 50X : 9+0.5L μm, 100X : 7+0.5L μm (L: Stitching length [mm]) | |||||

| Maximum number of measuring points in a single measurement |

4096 × 4096 pixels |

|||||

| Maximum number of measuring points |

36-megapixels |

|||||

| XY stage configuration | Length measurement module | • | NA | NA | • | |

| Operating range |

100 × 100 mm (3.9 × 3.9 in.) Motorized |

100 × 100 mm (3.9 × 3.9 in.) Manual |

300 × 300 mm (11.8 × 11.8 in.) Motorized |

100 × 100 mm (3.9 × 3.9 in.) Motorized |

||

| Maximum sample height |

100 × 100 mm (3.9 × 3.9 in.) |

30 mm (1.2 in.) |

30 mm (1.2 in.) |

210 mm (8.3 in.) |

||

| Laser light source | Wavelength | 405 nm | ||||

| Maximum output | 0.95 mW | |||||

| Laser class | Class 2 (IEC60825-1:2007, IEC60825-1:2014) | |||||

| Color light source | White LED | |||||

| Electrical power | 240 W | 240 W | 278 W | 240 W | ||

| Mass | Microscope body | Approx. 31 kg (68.3 lb) | Approx. 32 kg (70.5 lb) | Approx. 50 kg (110.2 lb) | Approx. 43 kg (94.8 lb) | |

| Control box | Approx. 12 kg (26.5 lb) | |||||

*1 Guaranteed when used in constant temperature and constant-temperature environment (temperature: 20˚C±1˚C, humidity: 50%±10%) specified in ISO554(1976), JIS Z-8703(1983).

*2 For 20x or higher, when measured with MPLAPON LEXT series objectives.

*3 When measured with dedicated LEXT objective.

*4 Typical value when measured with MPLAPON100XLEXT objective, and may differ from the guaranteed value.

*5 Guaranteed under Olympus Certificate System.

** The OS license of Window 10 has been certified for the microscope controller provided by olympus. Therefore, Microsoft's license terms are applied and you agree to the terms.Please refer to the following for Microsoft license terms.

https://www.microsoft.com/en-us/Useterms/Retail/Windows/10/UseTerms_Retail_Windows_10_english.htm

| Series | Model | Numerical Aperture (NA) | Working Distance (WD) (mm) |

|---|---|---|---|

| UIS2 objective lens | MPLFLN2.5x | 0.08 | 10.7 |

| MPLFLN5x | 0.15 | 20 | |

| Dedicated LEXT objective lens (10X) | MPLFLN10xLEXT | 0.3 | 10.4 |

| Dedicated LEXT objective lens (high-performance type) | MPLAPON20xLEXT | 0.6 | 1 |

| MPLAPON50xLEXT | 0.95 | 0.35 | |

| MPLAPON100xLEXT | 0.95 | 0.35 | |

| Dedicated LEXT objective lens (l |