-

Views:1025

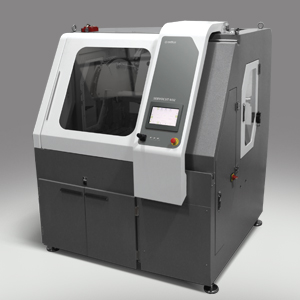

For cutting large and multiple specimens, ability to work with cut-off wheels up to Ø600 mm, cutting capacity up to Ø225 mm solid stock 100Hx500D mm for rectangular specimens, powerful 15 kW cutting motor with unique belt protection system, with electronic brake system, with variable cut-off wheel speed 600-2400 RPM, ability to set fixed peripheral speed of cut-off wheel from 20 to 60 m/s. overload display and protection system, accurate Servo motor driven table and wheel movement for precise and fast positioning, joystick with adjustable speed control, stainless steel table (772x710mm) with 560 mm

Y-axis movement range, Programmable with 10" HMI touch screen control, Siemens PLC control unit, automatic cut-off wheel diameter measurement and automatic starting position adjustment according to cut-off wheel wear, Positioning System allowing clamping several components simultaneously,

with automatic chop cutting and automatic table feed cutting systems, with automatic cutting feedrate control, with extra advanced cutting methods: "Rapid Pulse Cutting, Table Oscillation Cutting, Instafeed Cutting Automatic Chop Cutting, Automatic Table Feed Cutting" Powerful LED illumination, robust construction. Ready for operation. Without clamping devices, without recirculation cooling tank.

Includes a standard set of cutting consumables composed of;

*An assortment of 10 cut-off wheels with 600 mm dia.

*5 lt of METCOOL cooling fluid.

400 V, 3 phase, 50/60 Hz.

| Order No | 14 87 | 14 87-AX |

| Model | 602 | 602-AX |

| Max. Cut-off Wheel Diameter | Ø600 mm | Ø600 mm |

| Max. Cutting Capacity, Ø | Ø225 mm | Ø225 mm |

| Max. Cutting Capacity, HxD | 100x500 mm | 100x500 mm |

| Z-Axis Travel, (mm) | 340 mm | 340 mm |

| Y-Axis Travel, (mm) | 560 mm | 560 mm |

| X-AxisTravel, (mm) | - | 540 mm |

| T-Table Dimension, (mm) | 772x710 mm | 772x710 mm |

| T-Slot dimension, (mm) | 12 mm | 12 mm |

| Cutting Motor Power (S1) | 15 kW | 15 kW |

| Variable Wheel Speed | 600-2400 RPM | 600-2400 RPM |

| Wheel Diameter Measurement | Standard | Standard |

| Constant Peripheral Wheel Speed | Standard | Standard |

| Cutting Feedrate, (μm/s) | 20-5000 μm/s | 20-5000 μm/s |

| HMI Touch Screen Controller | 10 inch | 10 inch |

| Chop Cutting in Z- Axis | Auto | Auto |

| Table Feed Cutting in Y-Axis | Auto | Auto |

| Parallel Cutting in X-axis | - | Standard |

| Multi Target Cutting | - | Standard |

| Table Oscillating Cutting | Standard | Standard |

| Rapid Pulse Cutting | Standard | Standard |

| Smart Feed Control | Standard | Standard |

| StepCut; SegmentCut; DiagonalCut | Optional | Optional |

| Automatic Cleaning System | Optional | Optional |

| Central Lubricating System | Optional | Optional |

| Size, WxDxH, (cm) | 184x173x236 | 184x173x236 |

| Weight | 1600 kgs | 1600 kgs |

| Recirculation Cooling Uni | 200 lt | 200 lt |

| Additional Cutting Methods for SERVOCUT 602 | |

| GR 0928 | Software package for optional cutting methods; |

| *Diagonal Cut | |

| *Step Cut | |

| *Segment Cut | |

| Power Supply for SERVOCUT 602 | |

| GR 1226 | Transformer kit for 200-240 VAC, 3 phase, 50/60 Hz mains voltage |

| Cooling Systems for SERVOCUT 602 | |

| GR 1530 | Recirculation Cooling Tank, 200 lt, for SERVOCUT 602 |

| YM 8816 | Fine filter sheets for recirculation cooling tank (GR 1530), 10 pcs |

| GR 1559 | Coolant level sensor for recirculation cooling tank |

| Informs operator when coolant level is insufficient. | |

| GR 1540 | Magnetic collector rod for recirculation cooling tank |

| GR 0591 | BANDCOOL Band Filter Unit for SERVOCUT 602 |

| Band filter conveyor for the automatic collection and disposal | |

| of swarfs, with capacity of 150 lt., with fluid level indicator, | |

| complete system on wheels, with connection kit. | |

| 400V, 3-phase, 50 Hz | |

| YM 8877 | Filter roll for BANDCOOL, 50 m |

| Accessories for SERVOCUT 602 | |

| GR 0134 | FUMEFILTER Centrifugal Separator |

| Removes coolant mist for better illumination and viewing | |

| (To be ordered simultaneously together with the machine order) | |

| GR 0135 | Laser Alignment Unit |

| (To be ordered simultaneously together with the machine order) | |

| GR 0136 | Central Lubricating System with programmable maintenance cycle |

| (To be ordered simultaneously together with the machine order) | |

| GR 0137 | AUTOCLEAN Automatic Cleaning System for cutting chamber |

| (To be ordered simultaneously together with the machine order) | |

| GR 0140 | 3-lights warning beacon with audible signal |

| (To be ordered simultaneously together with the machine order) | |

| Clamping Devices for SERVOCUT 602 | |

| GR 0610 | Mechanical Clamping Device |

| GR 0611 | Serial Clamping Device for clamping multiple specimens from 1 to 4 |

| GR 0612 | Angular Precision Clamping Device in 3-Axis Direction |

| 15 02 | MBU 1031 Vertical Clamping Device with clamping shoe, clamping height up to 115 mm. |

| 15 04 | MK 10 22 Height Block, 70 mm |

| GR 0033 | Chain spanner set with anchor block |

| 15 00 | V-Block for holding parts above table slots |

| GR 0615 | Adjustable V-Support, Small (Height Range: 57-67 mm) |

| GR 0616 | Adjustable V-Support, Medium (Height Range: 65-85 mm) |

| GR 0617 | Adjustable V-Support, Large (Height Range: 85-115 mm) |

| GR 0618 | Adjustable V-Support, Extra Large (Height Range: 115-155 mm) |

| Treno Series Abrasive Cut-off Wheels (Pack of 10) | ||

| TRENO-NF | 19-090 | Ø 500 mm, for Non-Ferrous Steels |

| TRENO-M | 19-092 | Ø 500 mm, for Medium Hard Steels > 23-55 HRC < |

| TRENO-S | 19-093 | Ø 500 mm, for Hard Steels > 50-60 HRC < |

| Treno Series Abrasive Cut-off Wheels (Pack of 5) | ||

| TRENO-M | 19-097 | |