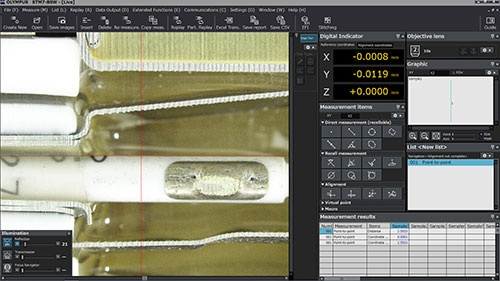

-

Refined Optical Performance

- The STM7 series uses the same UIS2 infinity-corrected optical system found in state-of-the-art optical microscopes.

- As a result, observed images have high resolution and high contrast, with aberration thoroughly eliminated to help ensure highly accurate measurement in minute detail.

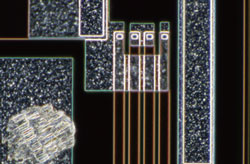

Reliable Measurements with a Stone Stage-Mounting Plate

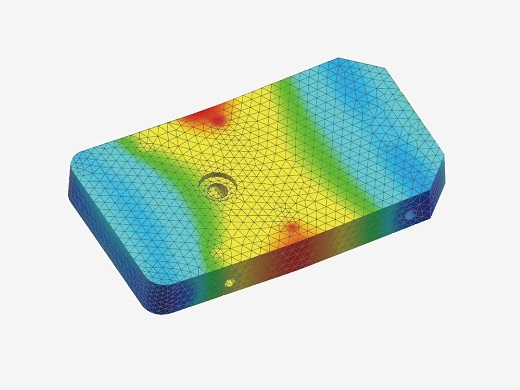

To further improve measurement accuracy, the STM7 series uses a highly durable, vibration-resistant frame with a granite surface plate. This stability enables sub-micron level measurements with minimal error.

STM7-LF FEM analysis

User-Friendly, High-Precision, 3-Axis Measurement

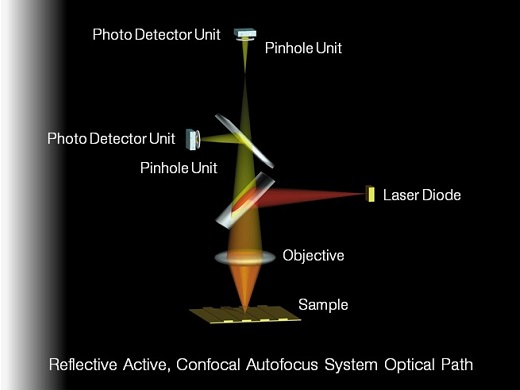

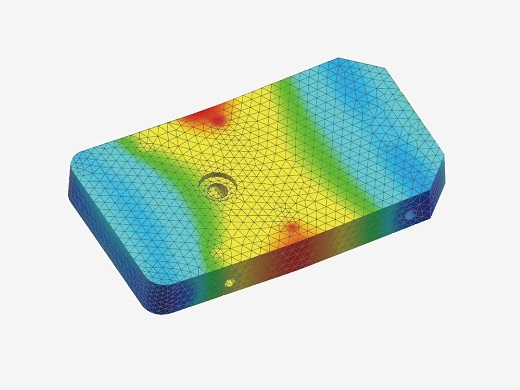

As modern manufacturing technology becomes increasingly miniaturized and precise, highly accurate measurements are even more essential—not only along the XY axis, but also along the Z-axis. Olympus responded by creating the first reflective active, confocal autofocus system.

Dependable Quality Based On a Strict Traceability System

- The accuracy of Olympus’ measuring microscopes is controlled by a strict traceability system, and Olympus even offers traceable calibration at the time of installation.

- Calibration certificate issued by Olympus Corporation Test & Analysis Center, and authenticated by ILAC-MRA calibration accreditation agencies (JCSS, JAB).

- Traceability systems vary depending on periods and countries/regions. The samples used in STM7 calibrations are calibrated in each country/region. Please ask Olympus for details

Reliable Modular Systems

Five configurations provide you with flexibility

to choose the features that you need.

Manual Models

STM7-SF STM7-CS100 (Stage 100 mm x 100 mm)

STM7-MF STM7-CS200 (Stage 200 mm x 200 mm)

STM7-LF STM7-CS300 (Stage 300 mm x 300 mm)

Motorized Models

STM7-MFA STM7-CS200 (Stage 200 mm x 200 mm)

STM7-LFA STM7-CS300 (Stage 30 x 300 mm)

| STM7-SF |

STM7-MF |

STM7-LF |

STM7-MFA |

STM7-LFA |

| Z-axis focus |

Manual |

Manual |

Motorized |

| Standard |

|

|

|

| Option |

|

|

|

Measurement objectives

Brightfield |

|

|

|

Focus navigator

STM7-FN |

|

|

|

Autofocus unit

STM7-AF |

- |

- |

|

Measurement support software

STM7-BSW |

|

|

|

Measurement support software

(Multiple Image Alignment /MIA and extend Focus Image/EFI)

STM7-ASW-ME |

|

|

|

OBSERVATION METHOD

BF: Brightfield

DF: Darkfield

DIC: Differential interference contrast

POL: Polarized light

: Option

: Option

Common Problems

- Short measurement stroke precludes the measurement of larger samples•Samples must be rotated because the X-axis measurement area is shorter than the Y-axis measurement area.

- Due to the narrow measurement range, it is impossible to line up large numbers of samples on the stage to measure them at the same time.

STM7 Solutions

- The STM7 features a 300 mm x 300 mm stage capable of measuring large samples, including 300 mm wafers and printed circuit boards.

- The X- and Y-axis measurement areas are equally long, eliminating the need to rotate samples.

- Long measurement areas for both the X and Y-axis allow multiple samples to be lined up on the stage for more efficient measurement.

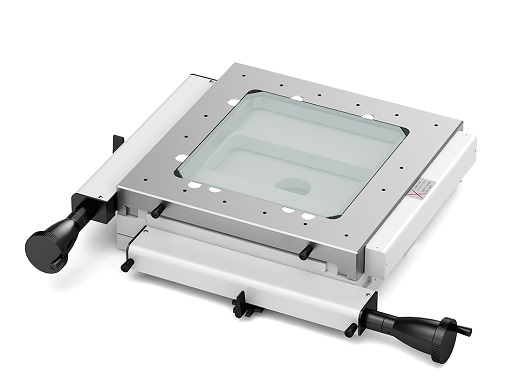

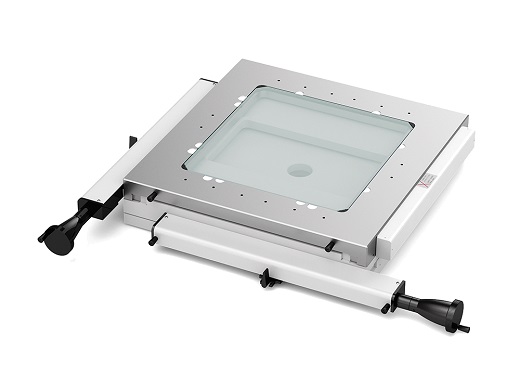

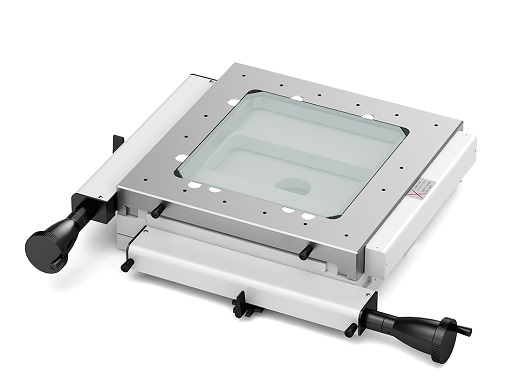

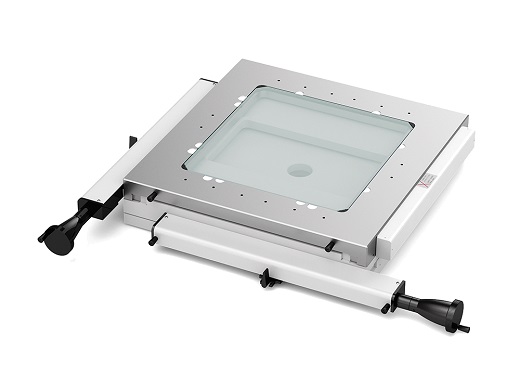

Maximum Measurement Stroke 300 mm x 300 mm

Three stages are available, each with a different measurement stroke - 100 mm x 100 mm, 200 mm x 200 mm, and 300 mm x 300 mm. Whether your samples are large or small, we offer a stage that fits your application.

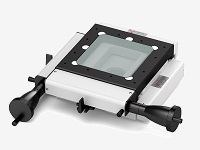

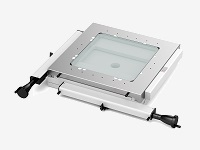

STM7-CS100

100 mm x 100 mm

STM7-CS200

200 mm x 200 mm

STM7-CS300

300 mm x 300 mm

Broad Range of Magnifications and Working Distances

Common Problems

- Most conventional measuring microscopes only accept a measuring objective or metallurgical objective, limiting the observation options.

STM7 Solutions

- The STM7 meets the requirements of a wide variety of observations. It responds to your needs at both low and high magnifications, enables the measurement of uneven samples requiring ultra-long working distance objectives, and even offers a variety of observation methods.

Measuring Objectives

The objectives’ very long working distance helps you be confident when focusing on samples with large peaks and troughs and minimizes the chance that the objective comes in contact with the sample.

Furthermore, their low-magnification capability enables wide areas to be observed in a single view.

Metallurgical Objectives

Metallurgical objectives enable high-magnification, high resolution observation comparable to that of optical microscopes.

What’s more, these objectives can be used for brightfield, darkfield, and DIC observation.

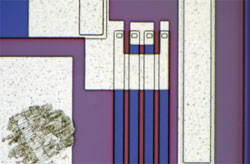

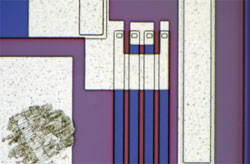

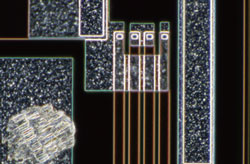

Brightfield image

Darkfield image